Pipe support systems are an extremely important aspect of building infrastructures in commercial and industrial settings. A robust, well-designed, and up-to-code pipe support system can lead to much greater safety and higher efficiency of your employees and expensive machinery.

The purpose of a pipe support system is to transfer the load from a pipe to the supporting structure, which holds and stabilizes this component, preventing sagging, vibrations, and wear and tear.

Without a proper support system in place, your piping will not operate optimally, which can lead to safety hazards, costly repairs, and downtime.

To make sure your pipe support system meets all the safety codes and regulations, we have come up with some key compliance checkpoints. With this information, you can easily ensure your pipe support system functions properly at all times and doesn’t violate any safety standards, so keep on reading till the end.

- Follow Commonly Recognized Codes and Standards for Pipe Support Systems

- Conduct Proper Load Assessment

- Select Proper Pipe Supports

- Compensate for Thermal Expansion or Movement

- Choice of Material

- Seismic and Wind Restraint

- Conduct Inspection, Maintenance, Documentation

The following are some key considerations that can help you keep your pipe support system up to code.

- Follow Commonly Recognized Codes and Standards for Pipe Support Systems

The first and probably the most important thing you need to do is to ensure your pipe support system complies with generally recognized codes. Make sure your pipe support system follows the updated and current codes, and there is documented evidence to prove that.

Some common codes include

- Local Building Codes and OSHA requirements

- NFPA Codes for Fire Protection Piping

- ASME B31.1 & B31.3 for power and process piping

- MSS-SP58/SP-69 Codes for pipe hanger and support standards

You also have to obtain key compliance certifications to ensure the system you are using follows the industry standards and to prevent common pipe support failures. These standards or certifications include the following.

- ANSI/MSS SP-58: This standard, published by the Manufacturers Standardization Society (MSS), covers the material, design, fabrication, and installation requirements for pipe hangers and supports.

- ASTM A123: This standard deals with protective hot-dip galvanized coatings on metal or steel products like pipes or pipe support systems to ensure corrosion and weather resistance.

- ANSI/UL 203: Developed by Underwriters Laboratories (UL), this standard outlines the design, construction, and performance requirements of pipe hangers in fire protection or suppression systems.

- Conduct Proper Load Assessment

Next up, you need to ensure that the supports you are using have been designed for your specific load requirements. You need to look at the net dead load by considering pipe weight, fluid weight, and insulation.

Also consider things like thermal expansion loads, dynamic and seismic loads, and occasional loads resulting from water hammer or valve operation.

This load assessment can prevent premature pipe support system failure, leading to its longer life and higher efficiency at all times. By making sure your pipe support system can support both operational and occasional loads, you prevent pipe damage and its associated risks altogether.

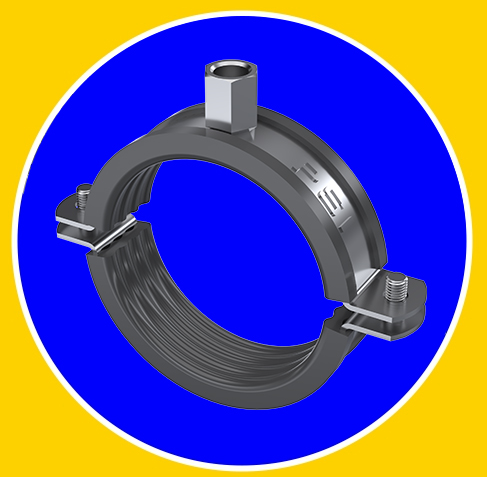

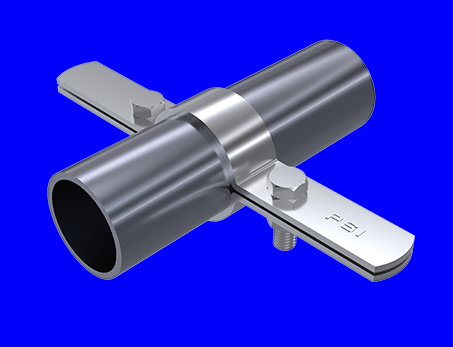

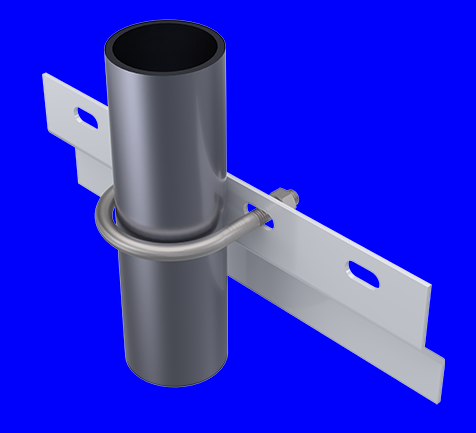

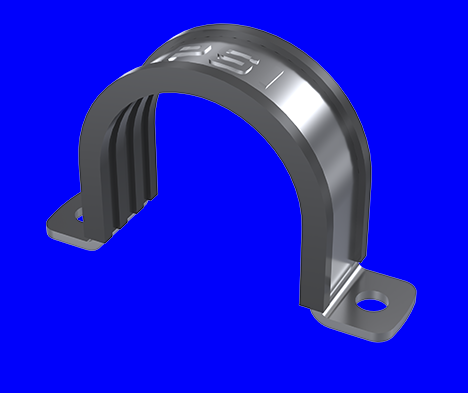

- Select Proper Pipe Supports

Consider the type of your pipes and then pick a support system designed specifically for it to make sure there are no compatibility issues that can affect its performance down the line.

- You can use dynamically loaded supports that offer variable resistance to movement. These are perfect for areas with seismic activity, rapid valve closure, and pump trips.

- If you wish to prevent pipe movement, a rigid support is what you need.

- To account for vertical movement by thermal expansion, the use of spring hangers is recommended.

- For directional control of the pipes, you can use anchors and guides.

- For equipment piping, vibration dampeners are recommended by experts.

- Compensate for Thermal Expansion or Movement

If the surrounding area of the pipes is hot or in case the fluid inside the pipes is very hot, you need to account for thermal expansion. In this case, you can use expansion joints, loops, or offsets to absorb the pipe movement.

Another option is the use of sliding supports, spring hangers, or rollers that facilitate a controlled movement of the pipe without major stress buildup.

- Choice of Material

Make sure the support material is compatible with the material of the pipe. This can slow down or even prevent corrosion or galvanic reactions. Here is what you can do.

- Make sure to use carbon steel support for carbon steel pipes.

- If the metal of the pipe and the support system are dissimilar, use a non-metallic insulator between the two.

- Metal pipes used outdoors should be coated with weather-resistant materials.

- Seismic and Wind Restraint

You also need to account for seismic and wind resistance standards if the pipes are being used in areas that are prone to earthquakes or high winds. In this case, your pipes must follow ASCE 7 seismic design provisions, IBC (International Building Code), and Manufacturer-specific standards for the seismic anchors or bracings you use.

- Conduct Inspection, Maintenance, Documentation

Ongoing inspections, maintenance, and documentation are crucial to ensure your pipe support system is always up to code. You need to regularly inspect this system for corrosion, wear and tear, and alignment.

Keep updated and maintained inspection and repair logs and conduct regular maintenance to show full compliance with industry standards at all times.

Conclusion

Having a good grasp of common pipe support system codes and standards is crucial if you wish to ensure employee safety and compliance with local and international regulations.

Apart from saving you from potential fines or legal complications, an up-to-code pipe support system also reduces accident and downtime risks, which can ensure your operation keeps running smoothly at all times.

The knowledge of general and location-specific pipe support system codes can help you prevent structural problems, pipe stability issues, and potential dangers, which is necessary for creating an efficient and secure workspace.

You can visit us at Power Solution PSI to order our up-to-code, premium quality and certified pipe support systems for all industrial applications.