There are very few countries in the world that match the unparalleled urban development or world-class infrastructure of the UAE. This region boasts iconic skyscrapers, mega malls, and countless industries, all of which come with advanced electrical systems.

Electrical cable management solutions are at the heart of these electrical systems that ensure both public safety and operational efficiency. There are different approaches to cable management in the UAE. However, cable trays and cable trunking systems are the most popular for their durability as well as installation efficiency.

This blog explores these cable management solutions in detail. It highlights their key features, types, and more. So, keep on reading till the end.

- What is a Cable Management System?

- What is a Cable Tray?

- What is a Cable Trunking System?

- Popular Cable Tray and Trunking Materials

- Best Practices for Choosing a Cable Management System in the UAE

What is a Cable Management System?

A cable management system aims to organize, route, or protect cables that we use for electrical, communication, or instrumentation purposes.

A recent study shows that the value of the global cable management system market stood at 25.3 billion in 2024. This market has the potential to grow to USD 36.3 billion by 2030 according to most estimates.

This system prevents the cables from overheating. It also reduces the need for maintenance or frequent repairs. The use of these systems prevents the risks of system failures in all industrial settings.

The use of cable management systems like cable trays or trunking facilitates future scalability of your electrical systems. The right system ensures safety as well as regulatory compliance for years to come.

What is a Cable Tray?

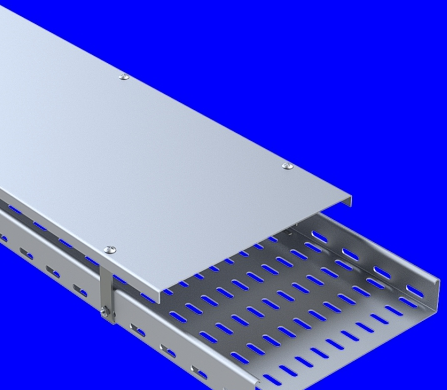

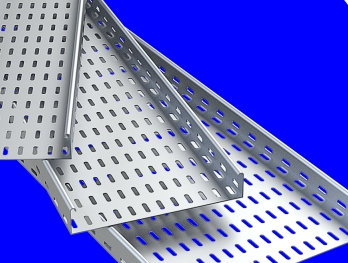

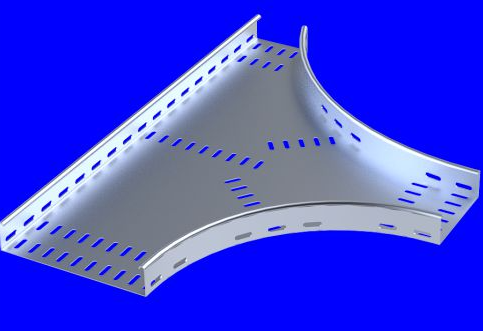

A cable tray system consists of a rigid structural framework that supports electrical cables in power distribution or communication applications. The rigid structures with perforations or cut-outs in these cable trays support cabling without the need to enclose them completely.

A report shows that cable tray systems hold the highest 35.12% share of the total cable management market. This system is either fully or partially open which gives you easier access to the cables. The open design also facilitates better heat dissipation. This cable management system can handle large cable volumes in all industrial settings.

Types of Cable Tray System

The following are some common types of cable tray systems that you should consider for your property in the UAE.

- Ladder Cable Trays

This common cable tray system comes with two side rails with transverse rungs. With this system, you get easy cable access along with excellent ventilation. These cable trays are perfect for high-load-bearing applications in power plants or oil & gas facilities.

- Perforated Cable Trays

Next up are the perforated cable trays that come with a solid bottom with small holes for ventilation. These trays give better cable support and a moderate airflow. These are perfect for commercial buildings as well as indoor installation.

- Solid Bottom Cable Trays

These cable trays feature fully enclosed bottoms that have no perforations whatsoever. These cable trays provide better cable support and maximum protection against dust.

These are perfect for use in data centers or near sensitive instrumentation where you need better electromagnetic interference resistance.

- Wire Mesh (Basket) Cable Trays

Another popular option is the wire mesh cable tray which features welded steel wires that form a mesh-like structure. These lightweight trays offer flexible routing.

These are perfect for IT rooms, offices, and for data and low-voltage cables.

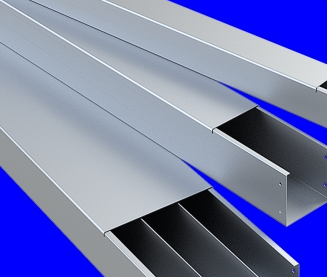

What is a Cable Trunking System?

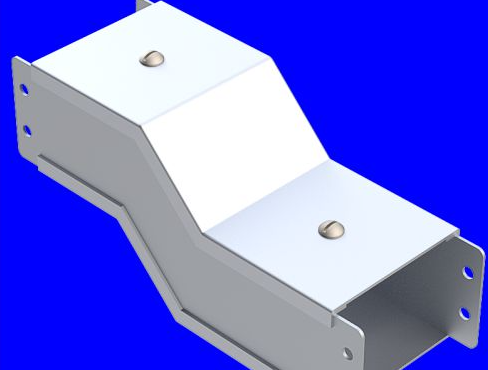

Cable trunking refers to fully or partially enclosed cable containment systems. This cable management system not only organizes cables but it also protects them from external threats like harsh weather or pests.

This cable management system provides better aesthetics than cable trays. You can use it in both residential or commercial settings where the cables run along visible surfaces.

Types of Cable Trunking Systems

The following are some common types of cable trunking systems that you need to know.

- Surface-Mounted Trunking

This type of trunking goes directly on the walls or ceilings. You can also use it on floor spaces. This type of trunking needs minimal structural modification. The ease of installation makes it perfect for retrofit projects.

- Flush-Mounted Trunking

This type of cable trunking is installed inside walls or floors. It allows for complete wire concealment as well as protection. This solution creates a clean architectural finish which makes it ideal for residential and commercial interiors.

- Compartment Trunking

Another popular option is the compartment trunking which features multiple internal sections. These trunking cable trays are effective in cases where you need to separate different control or power cables. These types of cables facilitate much better system organization. The risks of electromagnetic interference are also low with these cable trunking solutions.

Popular Cable Tray and Trunking Materials

The following are some common cable tray or trunking materials that you can find in the UAE.

- Aluminum

Research reveals that metal trunking systems will grow at a much faster rate in commercial settings for their higher durability as well as fire safety. Aluminum is a great option in industrial settings where you need greater corrosion-resistance.. Its exceptional strength makes it effective for longer spans. Aluminum also offers EMI-resistance due to its non-magnetic nature.

- Galvanized Steel

Another option is the hot-dip galvanized (HDG) steel which is perfect for outdoor use. This cost-effective material is ideal for external use due to its strong weather and corrosion resistance.

- Stainless Steel

If you wish to use the cable tray or trunking in aggressive environments or for heavy load applications you can go with stainless steel material. This material has a long service life. It also possesses exceptional impact resistance.

- PVC/FRP (Fiber Reinforced Plastic)

This material works best in industrial settings where there are many electrical hazards. The PVC/FRP (Fiber Reinforced Plastic) cable trays also possess great chemical resistance.

Best Practices for Choosing a Cable Management System in the UAE

Here are a few things you must look out for.

- Load Capacity

Make sure the cable management system supports the current cable load without sagging. This system should also have the capacity for future load expansion. Do not overfill the trays or trunking systems, as it can lead to the buildup of heat which increases safety risks.

- Application Environment

The location plays a big role in this decision. For indoor spaces you can use mesh or perforated trays as there is minimal dust. For outdoor use it is better to choose trunking systems made from stainless steel or hot-dip galvanized steel that resist environmental degradation.

- Cable Types

Make sure to consider the type of cable you need to place inside the system. You can opt for wider trays if you want to run power, data, or control cables through the same trays. This not only prevents electromagnetic interference but also reduces safety hazards.

- Regulatory Standards

Every cable management system in the UAE must adhere to IEC, BS, UL, and ISO standards. Your cable management system must show compliance with DEWA/ADDC/SEWA requirements as well.

This ensures you have the right approvals from the local authorities which saves you from legal troubles down the line.

- Design Considerations

Choose a cable tray or trunking system that suits the weight or future expansion needs. Make sure to invest in systems that come with flexible connections or joints that can accommodate thermal expansion.

Also ake sure to segregate telecommunication, data, or power cables to prevent interference.

- Long Term Value

The cost of a cable management system depends on things like the material and size of the installation. It is always a good idea to choose a system that delivers high long-term value instead of immediate cost savings.

High-quality systems need less maintenance and they eliminate safety hazards. These systems also ensure regulatory compliance which leads to greater operational efficiency.

Conclusion

A reliable cable management system is a critical element of the infrastructure of any building. The quality of this system affects the safety and overall efficiency in industrial settings. It also has a great influence on the scalability of electrical installations.

You need to choose between cable trays or trunking systems after carefully considering your project requirements in terms of costs, safety, and future readiness.

A perfect cable management system that adheres to all the safety standards can ensure the durability of your electrical systems for years to come.

You can visit us at Power Solution PSI to get the best cable tray or cable trunking wire management solutions to increase safety and productivity in all industrial settings.

FAQs

What is the real difference between a cable tray and a cable trunking?

Cable trunking is an enclosed system that offers greater protection to the wires. Cable trays have open or semi-open designs. These trays are ideal in cases where you need to carry large volumes of wire from point A to B in industrial settings. Trunking works best in offices or residential settings.

Which cable tray materials are ideal in the UAE climate?

UAE’s weather offers high temperatures as well as humidity. Due to these reasons cable trays that consist of hot-dip galvanized steel (HDG) or stainless steel work best in this region.

What benefits make mesh cable trays a better option in the UAE?

These cable trays feature a lightweight design which leads to faster installation. The open design of these trays allows for easy cable routing. The perforations in this cable tray provide much better ventilation than cable trunking systems.

What is the average lifespan of cable tray systems?

It mainly depends on the choice of material. A galvanized cable management system lasts 20–30 years. On the other hand stainless steel systems have a longer life of about 40 years.

Do you get heat dissipation with a cable tray?

Cable trays feature open designs that promote the flow of air. This reduces the cable temperature which leads to better durability even in the hot UAE climate.